Realizations

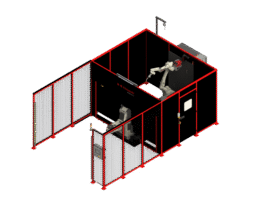

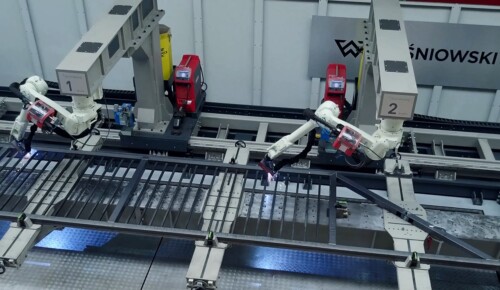

Wiśniowski

digital Customization in the Factory of the Future

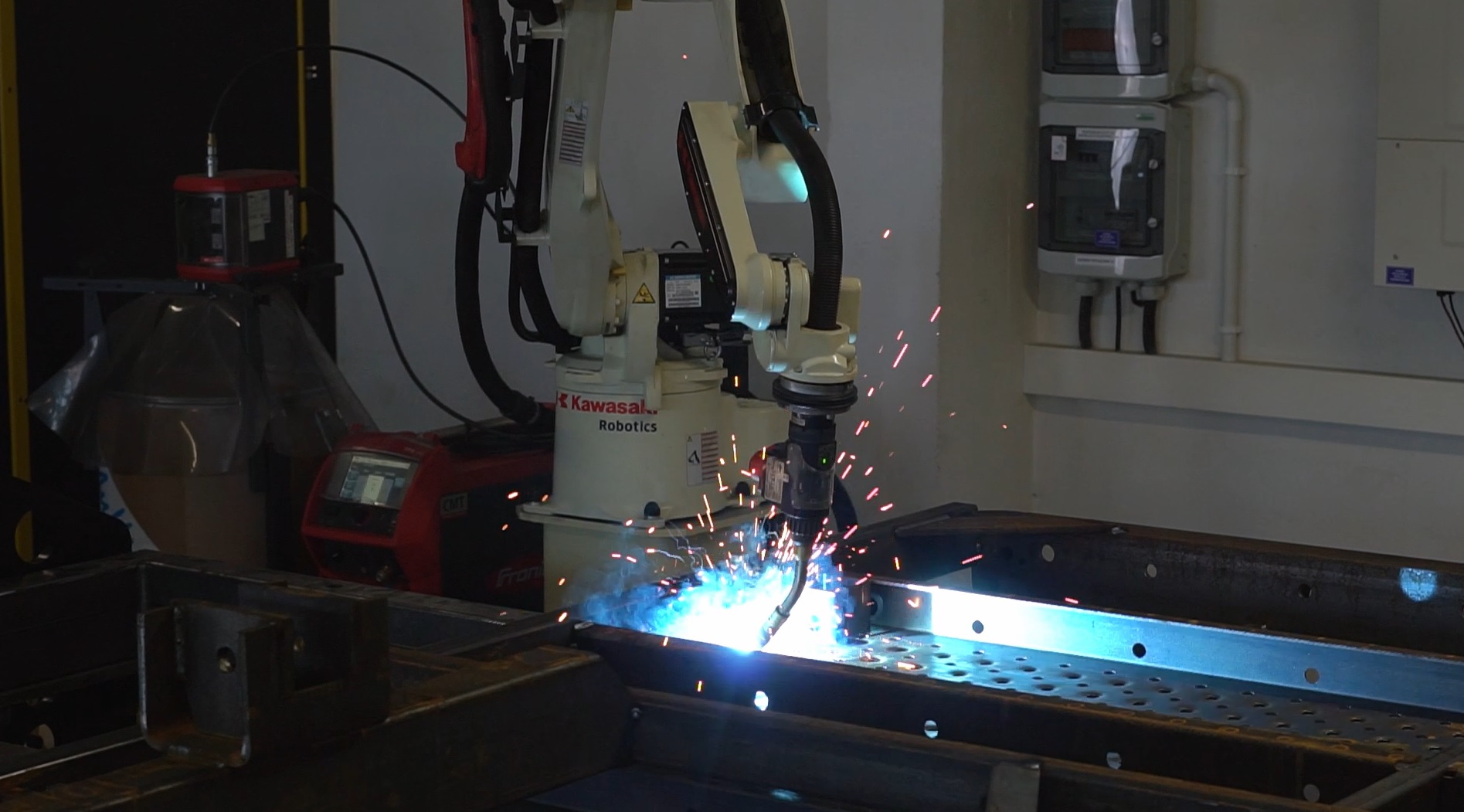

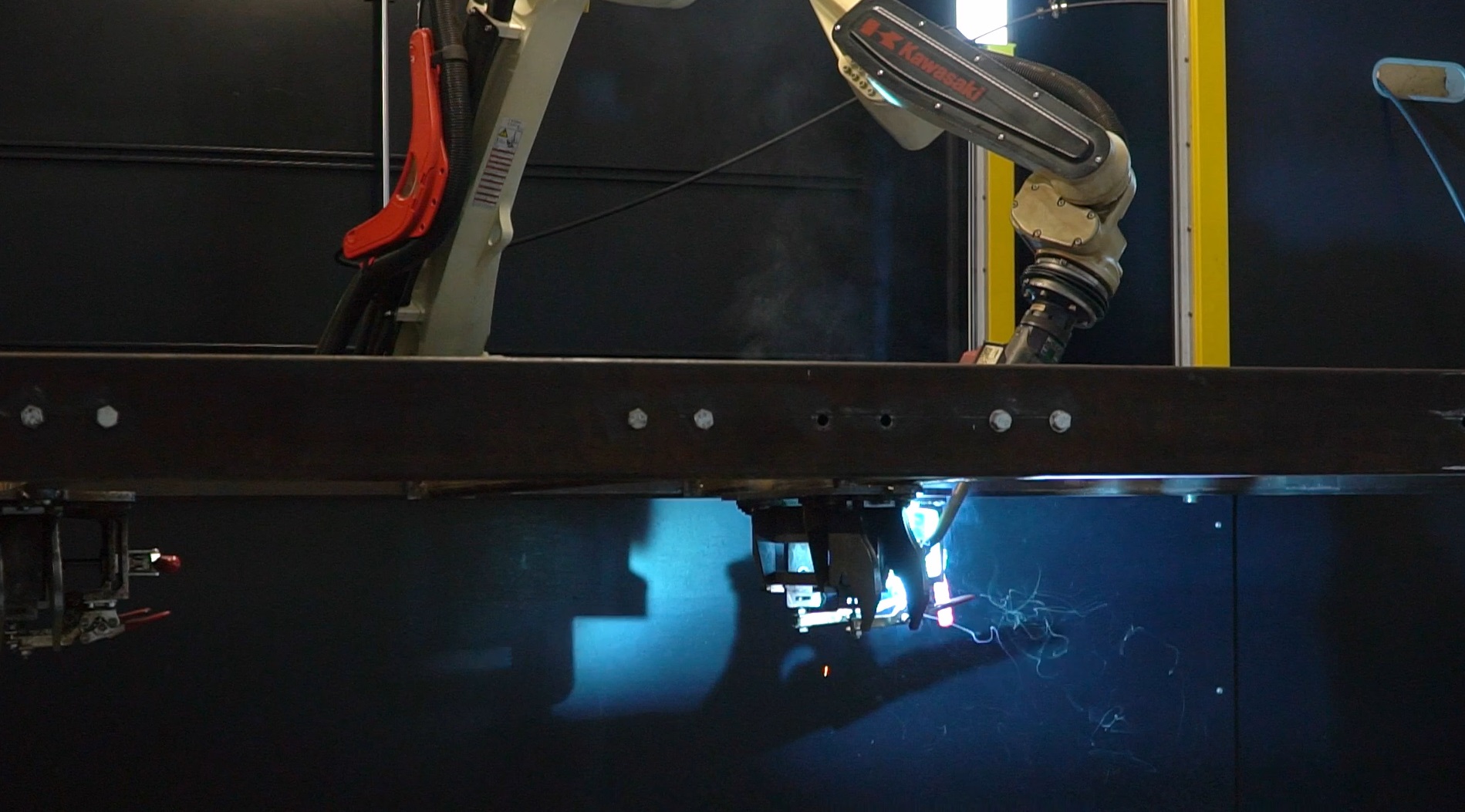

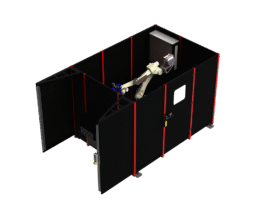

The Kawasaki Robotics BA006L welding robot features a longer arm than the Kawasaki Robotics BA006N without compromising its technical capabilities. Despite the extended arm, the entire design allows welding in tight spaces or on highly complex shapes. Its slim arm, hollow wrist, and integrated internal cabling enable the robot to weld any shape and place each weld with precision.

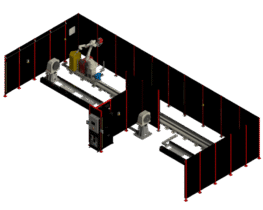

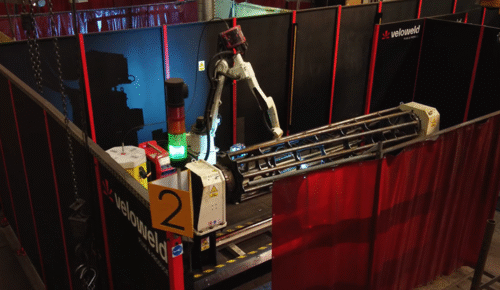

Unia Group

innovative Industry 4.0–Ready Production with VELOWELD

As part of the welding shop modernization project, an investment was made in four advanced robotic welding stations. Each station is equipped with a welding robot moving along a 10-meter rail and two positioners with a maximum load capacity of 2 tons each. To meet Unia’s production challenges, over 50 specialized welding applications and appropriate tooling for robotic spot welding and welding processes were developed.

More suggestions

Contact us

Przemysław Drzymała

Sales Director

VELOWELD Welding Competence Center

Przemysław Drzymała

Sales Director

VELOWELD Welding Competence Center

Szymon Habecki

Technical Director

VELOWELD Welding Competence Center

Szymon Habecki

Technical Director

VELOWELD Welding Competence Center

VELOWELD in Poland

branches

production halls:

- Gdańsk

- Kraków

- Szczecin

- Warszawa

- Katowice

- Wrocław

- Poznań

- Gdańsk

- Kraków

branches

- Gdańsk

- Kraków

- Szczecin

- Warszawa

- Katowice

- Wrocław

- Poznań

production halls:

- Gdańsk

- Kraków