WIŚNIOWSKI has nearly 30 years of experience in the construction industry. Investment in new technologies, improving quality and extending the offer, as well as innovativeness and entering new markets are the features which have made it a leader in its industry.WIŚNIOWSKI is a proof that Polish companies can be successful not only in domestic markets but also foreign ones. The WIŚNIOWSKI brand products are sold in 2500 outlets in Europe. Currently, the company employs nearly 1700 people.

Quality Management System. All components of WIŚNIOWSKI industrial fences and gates are laser cut, robot welded and subjectedto the best anticorrosive protection methods in the form of galvanising and powder coating. Zinc coating obtained by immersing a chemically cleaned construction in a liquid zinc protects elements of the WIŚNIOWSKI fences against corrosion for decades. The aesthetic and unique look of the final product is additionally provided by polyester protective coating in any of over 200 RAL colours.

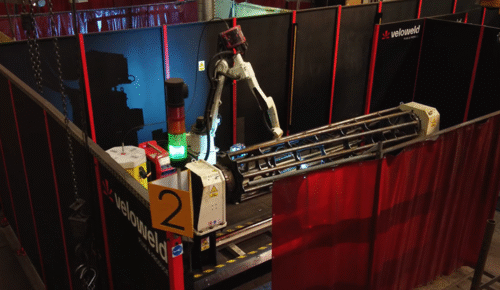

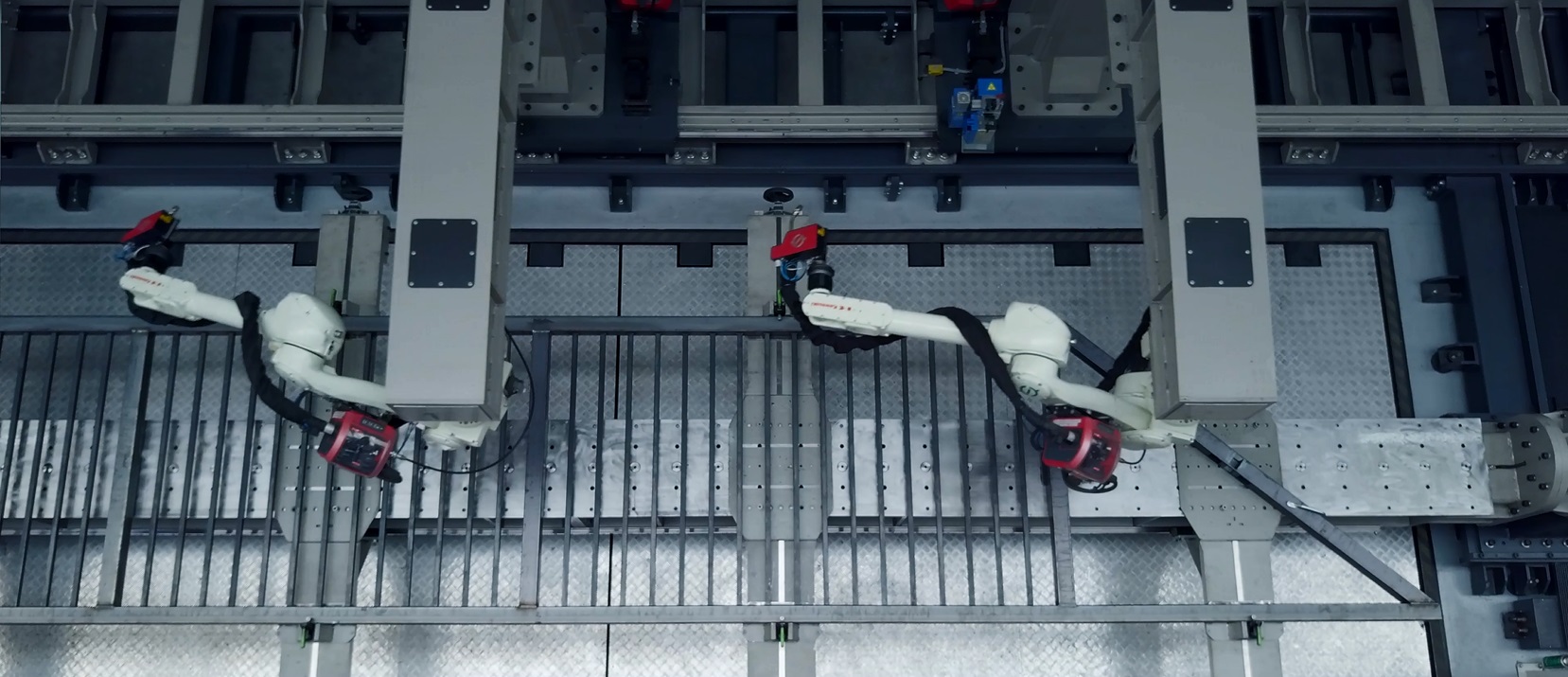

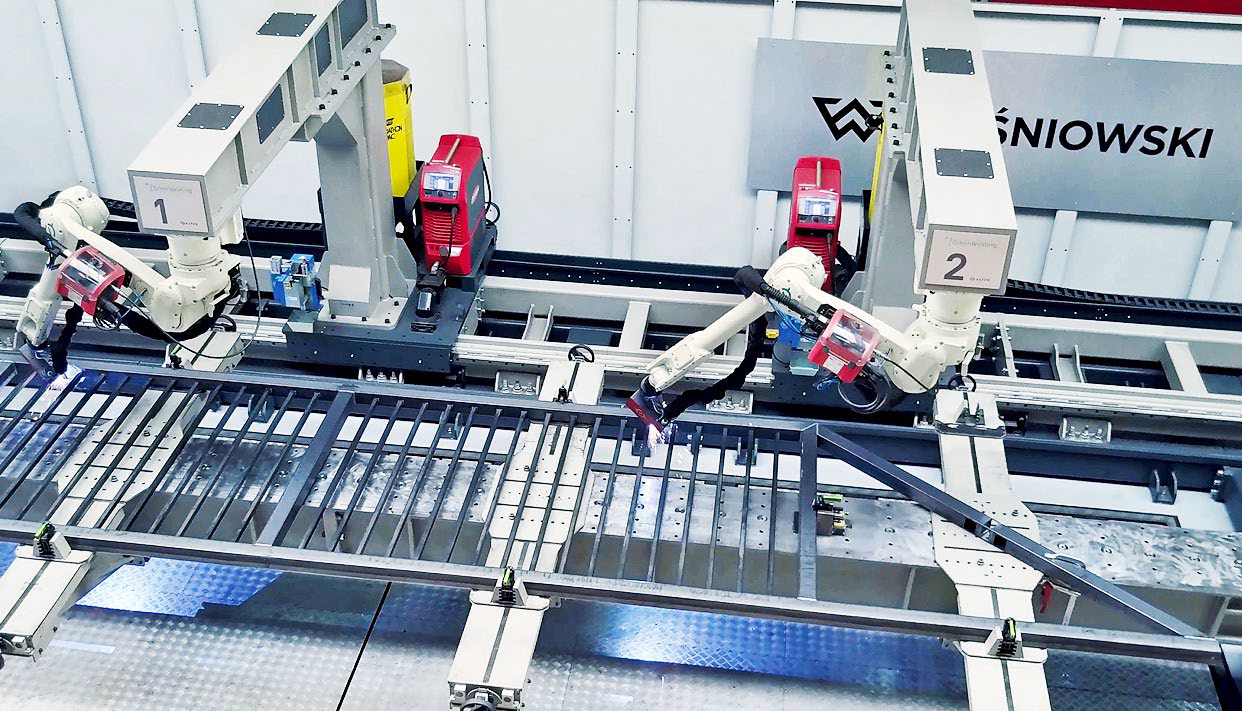

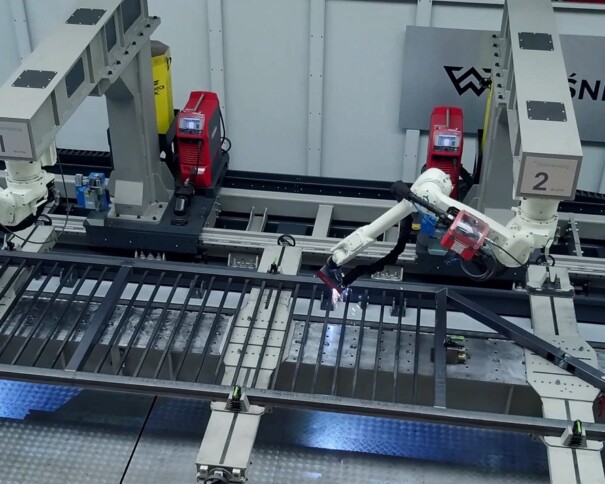

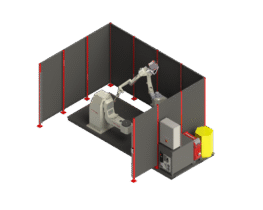

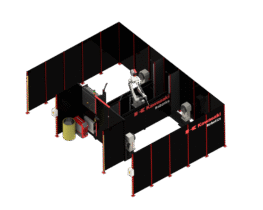

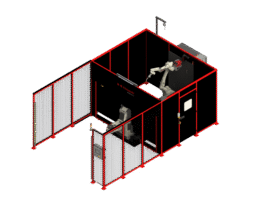

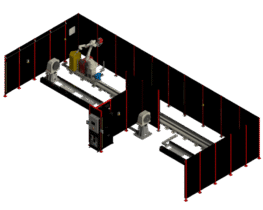

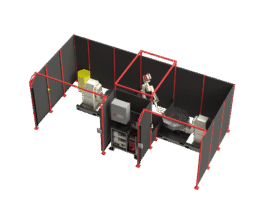

The robotic cell is powered by two Kawasaki Robotics RA006L industrial robots designed for welding, along with welding equipment. The robots move along a 17-meter track, enabling the welding of large-sized gates. The use of two rotators allows for the station’s versatility – the robots can simultaneously weld a single object on a larger positioner or operate independently on both stations, producing two gates simultaneously. The positioners’ modularity allows for further expansion of the system or modification to adapt to the changing needs of the production facility. The robots are mounted on column-and-boom arms, allowing for optimized workflow efficiency and maximizing the robots’ reach.

An additional benefit for the station operators is the use of automatically controlled troughs under the rotators, which are recessed into the floor when the gate rotates and are flush with the floor during assembly and disassembly by the operators. This solution simplifies work and ensures employee safety.

By investing in robotic welding stations, significant time savings were achieved in the order fulfillment process and the work of programmers and welding station operators was optimized. The robots ensure consistent welding quality. The welds are exceptionally aesthetic and perfectly prepared for subsequent production stages.

Thanks to the implemented system, it was possible to systematize the production process itself – from production planning, through execution, to the quality of the final product. This process has become more predictable and accurate. The system has also shortened the turnaround time for serial orders – particularly in the context of export orders.

The robotization of production has increased efficiency, improved quality, and stabilized technological processes, while also shortening the time required for operations. The introduction of this system also enabled optimal use of the production floor space. Automation also allowed for maintaining the dynamics and fluidity of production, as well as producing to individual orders.