Realizations

Anipol

robotic welding in the furniture industry

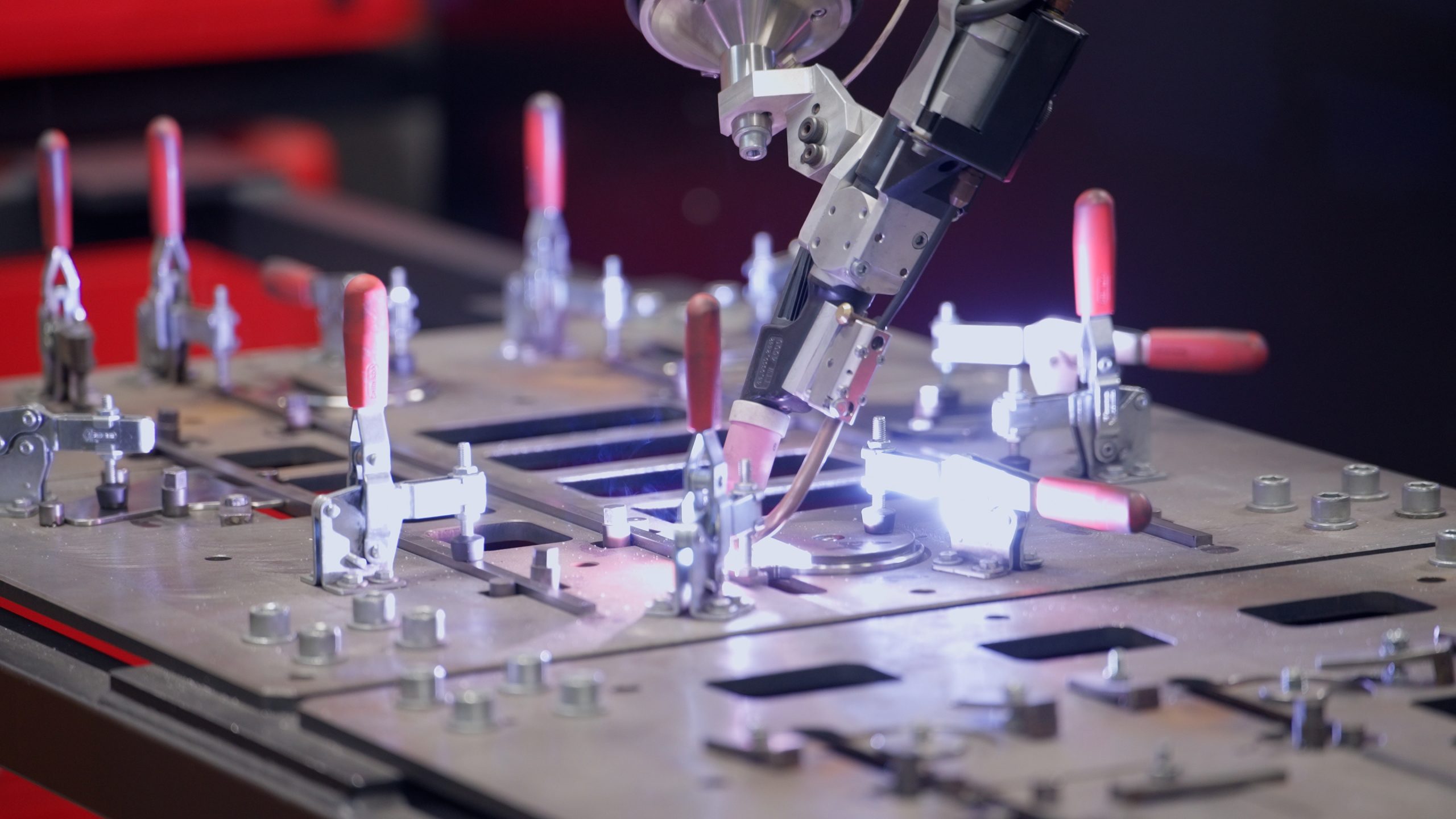

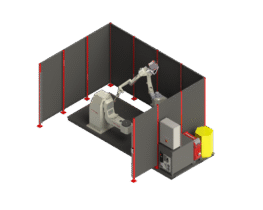

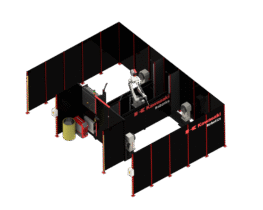

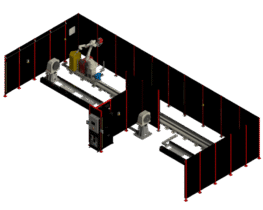

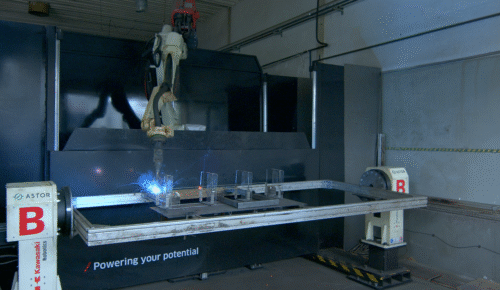

When deciding to invest in robotization, Anipol considered various solutions, from welding machines to fully automated welding cells. The most important element of the station, which allowed for high process efficiency, was the H multi-positioner. Rotators of this type have two rotating stations with horizontal axes, separated by a screen. At any given moment, both the robot and the operator are working simultaneously, with the operator removing the welded parts and loading the components for the next cycle. The Kawasaki Robotics RA006L welding robot was selected for the set with the positioner, guaranteeing high travel speed and high repeatability.

Impex

modern welding robotization in the metal industry. Short-run welding services

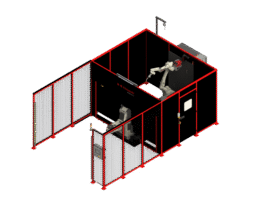

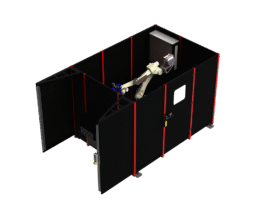

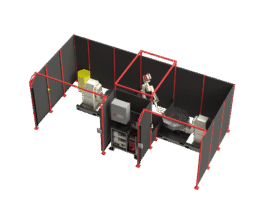

The company’s latest investment is a robotic cell for use with a Kawasaki Robotics robot. The welding robot is used to operate two of the many devices equipped at Impex: one for display component assembly and the other for welding shafts for the steelworks being handed over. The welding cell is used to prepare a prefabricated cell for robotic welding.

More suggestions

Contact us

Przemysław Drzymała

Sales Director

VELOWELD Welding Competence Center

Przemysław Drzymała

Sales Director

VELOWELD Welding Competence Center

Szymon Habecki

Technical Director

VELOWELD Welding Competence Center

Szymon Habecki

Technical Director

VELOWELD Welding Competence Center

VELOWELD in Poland

branches

production halls:

- Gdańsk

- Kraków

- Szczecin

- Warszawa

- Katowice

- Wrocław

- Poznań

- Gdańsk

- Kraków

branches

- Gdańsk

- Kraków

- Szczecin

- Warszawa

- Katowice

- Wrocław

- Poznań

production halls:

- Gdańsk

- Kraków