Realizacje

Anipol: robotic welding in the furniture industry

Anipol is a family-owned company that has been operating in the Polish market for over a decade, including the last five in the furniture industry. Constantly improving competitiveness is embedded in the daily operations of companies in this sector. Efficient work organization, effective human resource management, and investments in modern technologies allow us to secure new contracts and maintain our leading position in supplying renowned furniture stores.

Among other things, Anipol supplies welded metal desk legs to various furniture manufacturers, including global ones. One contract involves the delivery of 30,000 high-quality components per month for five years.

Companies producing metal parts that provide welding and grinding services are facing a shortage of trained welders and high staff turnover, with employees seeking employment abroad. This was one of the main reasons that prompted Anipol to explore the existing automated and robotic welding solutions available on the market. Organizing the production of these semi-finished products based on the work of 6-9 welders and a welding machine was no longer sufficient to meet the competitive challenge.

Robotization of the welding of desk legs would ensure the fulfillment of orders under contracts and at the same time would free up jobs – transferring welders to non-contractual tasks.

Achieving consistent, repeatable quality and high productivity with orders of 30,000 pieces and manual welding is virtually unattainable, as each employee has unique characteristics. Welding even dozens of pieces per month is very burdensome for human health, so the use of a robot also serves as an argument for increased workplace safety. The increase in productivity was intended to go hand in hand with improved piece quality, which plays a crucial role for global furniture chains. The consistent quality of robotic welding would allow these requirements to be met without fear of rejection during collection by furniture chain representatives.

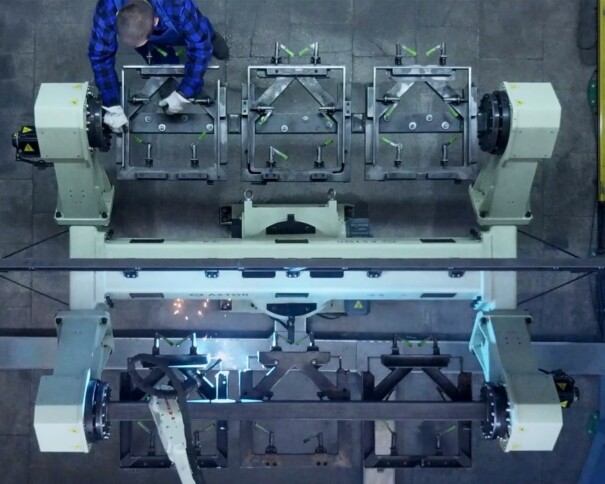

The project focused on a single detail – desk legs – featuring two circumferential welds with a total length of 160 mm. Why this detail? The best answer lies in the numbers – annual demand for this detail is over 100,000 pieces, and the manual welding process required six workers per shift.

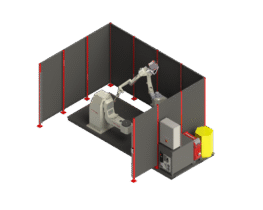

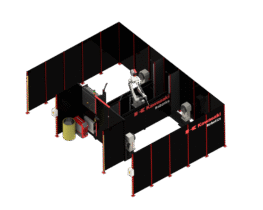

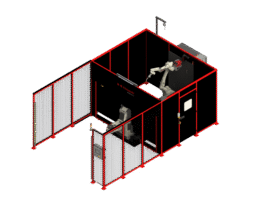

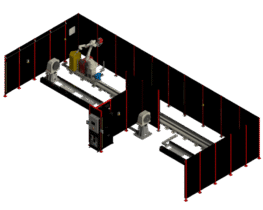

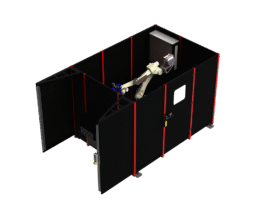

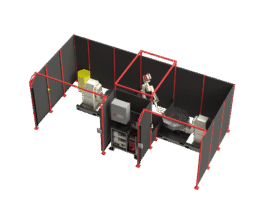

The most important element of the station, which allowed for high process efficiency, was the H multi-positioner. These positioners feature two rotary stations with horizontal axes, separated by a shutter. At any given moment, both the robot and the operator are working simultaneously, picking up welded parts and installing components for the next cycle.

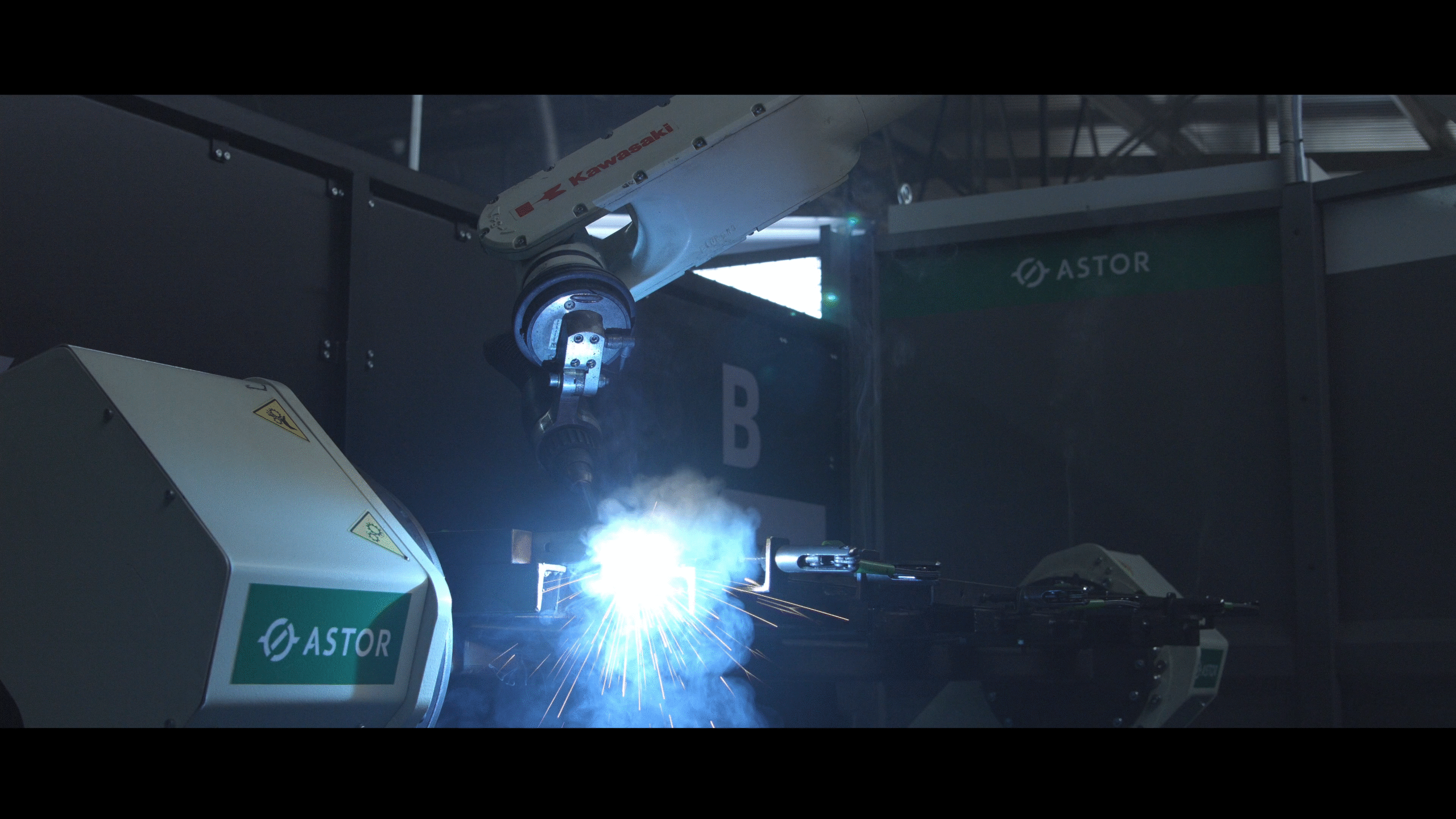

The positioner kit was complemented by a Kawasaki RA006L welding robot, ensuring high travel speeds and excellent repeatability. A welding kit wouldn’t be complete without a welding power source. For this project, a Fronius power source was selected, compatible with Kawasaki welding robots.

The robotic cell is operated via an application for operators on the Astraada One panel. This allows for the adjustment of all device parameters at the cell – from the robot to the positioner, welding power source, cleaning station, and safety system.

The entire station was fenced off by solid panels within the robot’s reach and mesh panels at the operator’s work area. Additionally, the operator’s work area was protected by light curtains.

Modern robotics significantly increases production efficiency without eliminating human labor. Welders who once held this position still work for the company, welding other components.

Anipol is a family-owned company that has been operating in the Polish market for over a decade, including the last five in the furniture industry. Constantly improving competitiveness is embedded in the daily operations of companies in this sector. Efficient work organization, effective human resource management, and investments in modern technologies allow us to secure new contracts and maintain our leading position in supplying renowned furniture stores.

Among other things, Anipol supplies welded metal desk legs to various furniture manufacturers, including global ones. One contract involves the delivery of 30,000 high-quality components per month for five years.

Companies producing metal parts that provide welding and grinding services are facing a shortage of trained welders and high staff turnover, with employees seeking employment abroad. This was one of the main reasons that prompted Anipol to explore the existing automated and robotic welding solutions available on the market. Organizing the production of these semi-finished products based on the work of 6-9 welders and a welding machine was no longer sufficient to meet the competitive challenge.

Robotization of the welding of desk legs would ensure the fulfillment of orders under contracts and at the same time would free up jobs – transferring welders to non-contractual tasks.

Achieving consistent, repeatable quality and high productivity with orders of 30,000 pieces and manual welding is virtually unattainable, as each employee has unique characteristics. Welding even dozens of pieces per month is very burdensome for human health, so the use of a robot also serves as an argument for increased workplace safety. The increase in productivity was intended to go hand in hand with improved piece quality, which plays a crucial role for global furniture chains. The consistent quality of robotic welding would allow these requirements to be met without fear of rejection during collection by furniture chain representatives.

The project focused on a single detail – desk legs – featuring two circumferential welds with a total length of 160 mm. Why this detail? The best answer lies in the numbers – annual demand for this detail is over 100,000 pieces, and the manual welding process required six workers per shift.

The most important element of the station, which allowed for high process efficiency, was the H multi-positioner. These positioners feature two rotary stations with horizontal axes, separated by a shutter. At any given moment, both the robot and the operator are working simultaneously, picking up welded parts and installing components for the next cycle.

The positioner kit was complemented by a Kawasaki RA006L welding robot, ensuring high travel speeds and excellent repeatability. A welding kit wouldn’t be complete without a welding power source. For this project, a Fronius power source was selected, compatible with Kawasaki welding robots.

The robotic cell is operated via an application for operators on the Astraada One panel. This allows for the adjustment of all device parameters at the cell – from the robot to the positioner, welding power source, cleaning station, and safety system.

The entire station was fenced off by solid panels within the robot’s reach and mesh panels at the operator’s work area. Additionally, the operator’s work area was protected by light curtains.

Modern robotics significantly increases production efficiency without eliminating human labor. Welders who once held this position still work for the company, welding other components.

“The Kawasaki Robotics robot, working with the K-Positioner and one operator per shift responsible for workpiece loading, meets – and even exceeds – our planned expectations. Previously, welders could produce one piece per minute. Now, the robot welds three pieces in just 1 minute and 15 seconds.”

Tell: Kamil Sordyl

Director of the Anipol Production Plant

More suggestions

Contact us

Przemysław Drzymała

Sales Director

VELOWELD Welding Competence Center

Przemysław Drzymała

Sales Director

VELOWELD Welding Competence Center

Szymon Habecki

Technical Director

VELOWELD Welding Competence Center

Szymon Habecki

Technical Director

VELOWELD Welding Competence Center

VELOWELD in Poland

branches

production halls:

- Gdańsk

- Kraków

- Szczecin

- Warszawa

- Katowice

- Wrocław

- Poznań

- Gdańsk

- Kraków

branches

- Gdańsk

- Kraków

- Szczecin

- Warszawa

- Katowice

- Wrocław

- Poznań

production halls:

- Gdańsk

- Kraków