VELO H

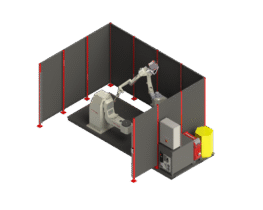

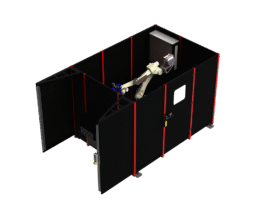

Welding cell with

an H-type positioner

VELO H

Welding cell with

an H-type positioner

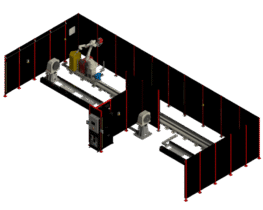

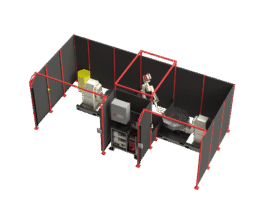

A highly efficient, compact welding station designed for high-volume serial production. It is equipped with a welding multi-positioner with two work areas. While the robot is welding on the active side, the operator has time to unload and load new components on the passive side. This solution is ideal for serial production of components up to 2.5 meters in length.

Welding power source

We partner with the largest manufacturers of welding power sources, which allows us to select them individually based on the client’s preferences. When choosing a power source, we also ensure that the welding process is optimised as much as possible. In our robotic welding stations, we use welders from top brands, including Fronius, SKS, ESAB, and EWM.

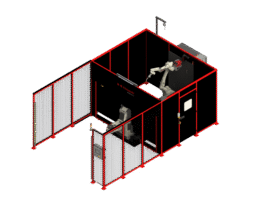

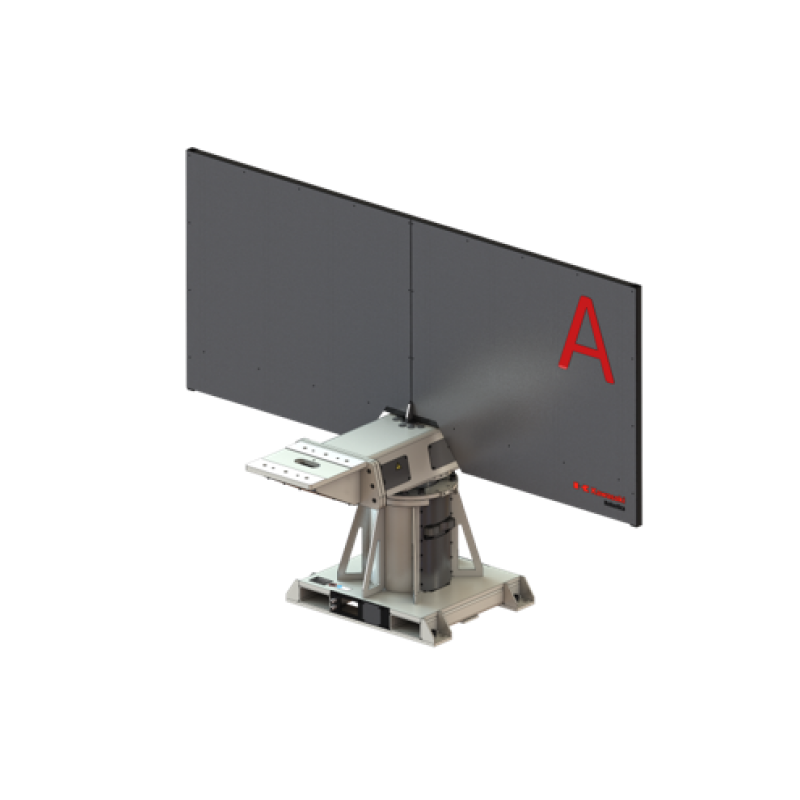

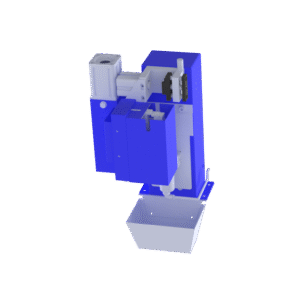

Cleaning Station

A device that enables automatic cleaning of the torch nozzle. It is equipped with functions for automatic welding wire cutting and application of anti-spatter fluid.

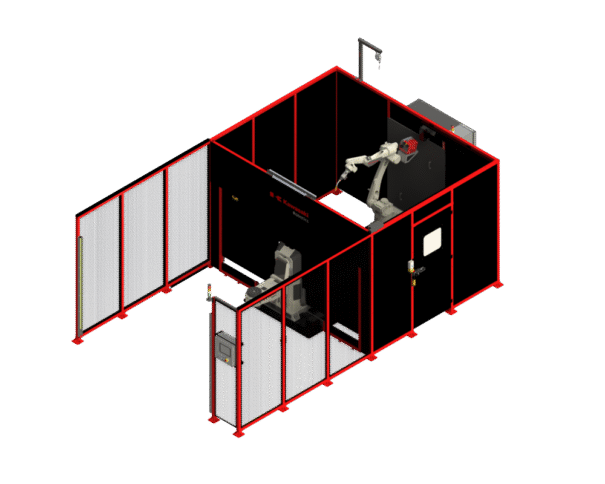

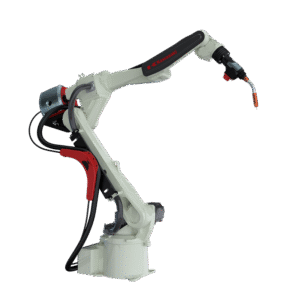

Welding Robot BA006L and BA006N

The Kawasaki Robotics BA series robot is dedicated to robotic welding. Depending on the size of the parts being welded, we can use a robot with a reach of 1 450 mm (BA006N) or 2 036 mm (BA006L) in the robotic welding station. The combination of the robot’s slender design and a hollow wrist allows it to weld parts with complex geometry while maintaining maximum arm rigidity in hard-to-reach areas.

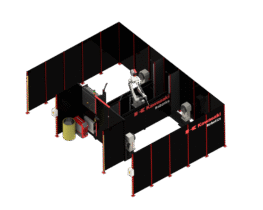

Realizations

Anipol

robotic welding in the furniture industry

When deciding to invest in robotization, Anipol considered various solutions, from welding machines to fully automated welding cells. The most important element of the station, which allowed for high process efficiency, was the H multi-positioner. Rotators of this type have two rotating stations with horizontal axes, separated by a screen. At any given moment, both the robot and the operator are working simultaneously, with the operator removing the welded parts and loading the components for the next cycle. The Kawasaki Robotics RA006L welding robot was selected for the set with the positioner, guaranteeing high travel speed and high repeatability.

Are you looking for a tailored solution?

Looking for a ready-made welding station for your company?

Or do you need a customized solution?

Contact us

Przemysław Drzymała

Sales Director

VELOWELD Welding Competence Center

Przemysław Drzymała

Sales Director

VELOWELD Welding Competence Center

Szymon Habecki

Technical Director

VELOWELD Welding Competence Center

Szymon Habecki

Technical Director

VELOWELD Welding Competence Center

VELOWELD in Poland

branches

production halls:

- Gdańsk

- Kraków

- Szczecin

- Warszawa

- Katowice

- Wrocław

- Poznań

- Gdańsk

- Kraków

branches

- Gdańsk

- Kraków

- Szczecin

- Warszawa

- Katowice

- Wrocław

- Poznań

production halls:

- Gdańsk

- Kraków