The Polmo S.A. Automotive Equipment Plant is the largest industrial facility in Brodnica. It is a company with a long tradition, whose management, faced with growing quality demands from customers, decided to invest in modern technologies.

The plant produces a wide range of high-quality spare parts and equipment for the automotive industry. The core product range consists of steel fuel tanks and compressed air tanks for vehicles such as trucks, trailers, semi-trailers, and buses. Welding is a key process in the production of compressed air tanks.

The tanks must meet particularly stringent quality requirements imposed by European Union regulations – these are stringent for safety reasons. Furthermore, the customers of these products are primarily international automotive companies, which expect the supplier to adhere to their procedures and standards – not only in terms of quality but also pricing and operational requirements – including fast order fulfillment.

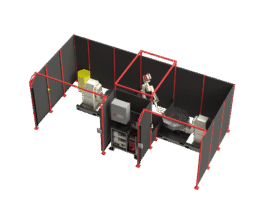

Seeking a way to meet these numerous demanding requirements, the then-POLMO management decided to comprehensively automate and robotize one of the plant’s two welding lines. From a business perspective, the investment’s goal was to increase the plant’s production capacity – the initial goal was to produce 55,000 units of one type of tank per year per line. From an engineering perspective, the investment was to ensure consistent Class B welding quality; this is the highest quality class in welding.

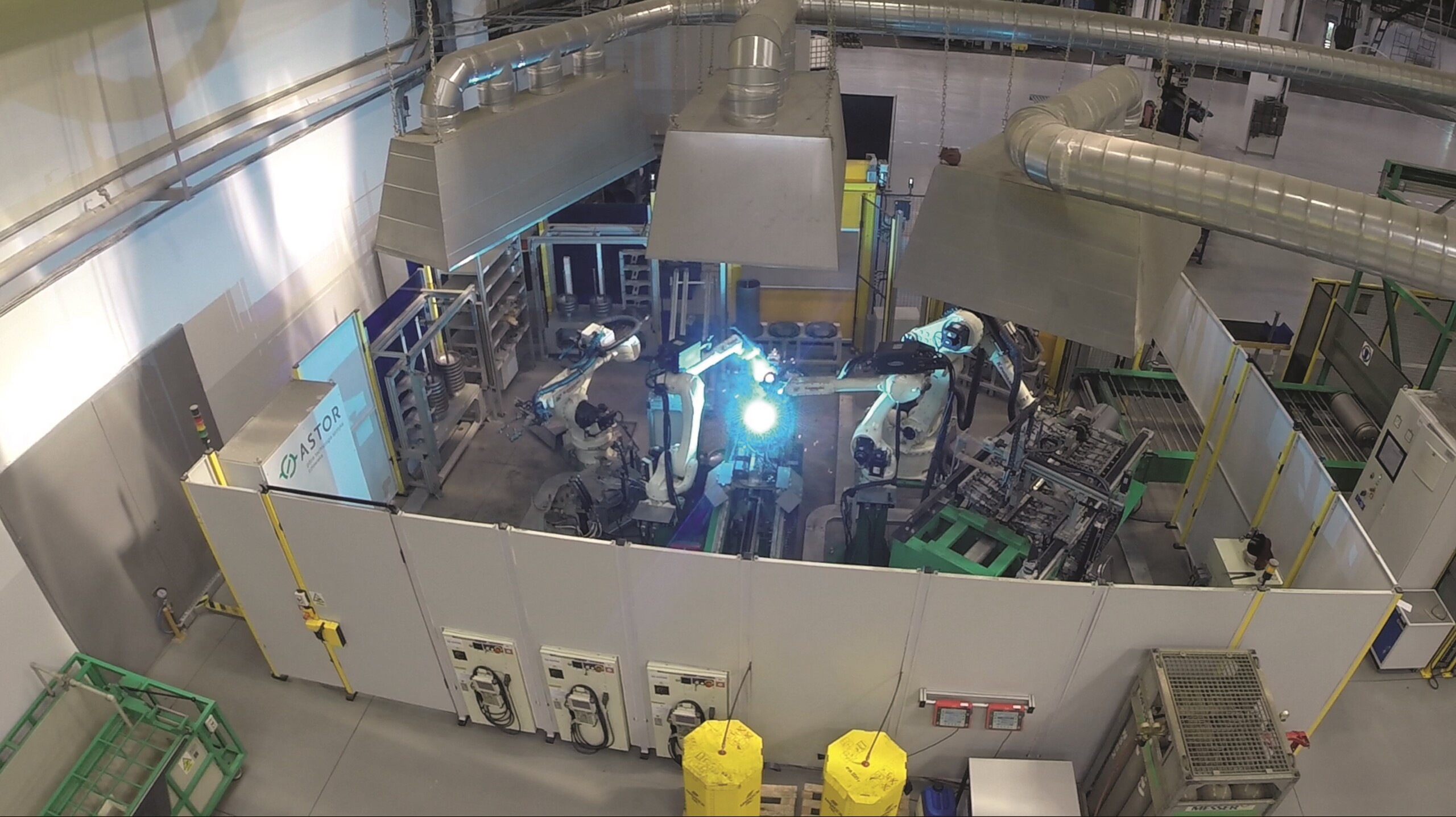

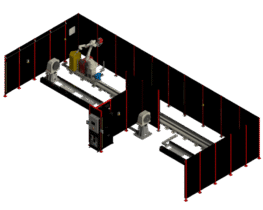

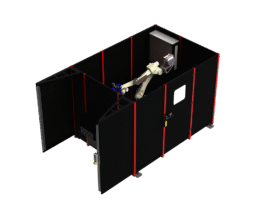

The robotic welding line is operated by five robots that perform the tank welding and weld cleaning processes. The entire tank manufacturing process is automated: from loading the components to delivering them to the finished tank marking station. Workers operating the station load the shells, bottoms, and nozzles into the magazines. The robots retrieve the components from the magazines and carry out the assembly, welding, and placing them on a conveyor to the cleaning zone. A manipulator retrieves the tank from the feeder and passes it to another robot, which begins weld cleaning. After cleaning, the tank passes through a cooling tunnel and is then transferred to a station operated by an operator, who positions the tank in the micro-percussion marking station. The tanks are marked with individual numbers, allowing for the replication of the production process for each product and guaranteeing its quality. After labeling, the operator moves the tank to a leak testing chamber. This test involves filling the tank with water containing a corrosion inhibitor to a specified pressure level and monitoring any pressure drop over time. After the test, the tank production line is completed, and the products are sent to the powder coating facility.

The modernization not only allows for the continuous improvement of product quality and increased production efficiency, making the plant competitive in both Polish and international markets, but also improves work comfort and enhances professional qualifications among employees of one of the largest employers in Brodnica.